|

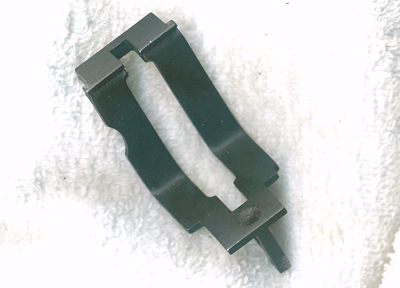

International trigger groups. Pictured is a early production group with the drawing number IHC D6528290.

These groups "as issued" from IHC, had early C5546008 IHC hammers, IHC marked safeties, stamped IHC trigger guards, without

the dimples and IHC pins. These groups were used from serial number 4,400,000 to approximately 4,600,000.

Later IHC D6528290 trigger groups had C-5546008 IHC hammers, IHC marked safeties, IHC stamped trigger guards,

without the dimples and IHC pins. These were used after testing failures late 1953.

The next IHC D6528290 trigger groups had C5546008 IHC hammers, F marked safeties, stamped IHC trigger

guards with dimples and dimpled IHC pins. These were found used during the end of 4.6 "Gap letter" production.

The last IHC D6528290 trigger groups had 5546008 IHC hammers with the heat lot code, F marked safeties, IHC stamped

trigger guards with the dimpled lugs, and dimpled IHC pins.

The 6528290 IHC trigger groups were used next. All have 5546008 IHC hammers with the heat lot letter, F

marked safeties, dimple lugged IHC stamped trigger guards, IHC triggers and IHC dimpled pins. Used throughout the rest

of IHC production.

| IHC had dimples |

|

The International stamped trigger guard lugs that lock up into the reciever usually have a dimple in the middle.

The hammer and trigger pins have this same feature. Early IHC D6528290 trigger groups will not have the dimples on the

trigger guard lugs.

International used three different drawing numbers on their bolts. The first bolt was marked D6528287 IHC,

the D-6528287 IHC is believed to be a revision of the D6528287IHC bolt and the last 6528287 IHC. Heat lots were usually

AS, B12, C19, D19, U and X. Others do exist. It is being researched that the D-65 bolts were a revision to

the D65 bolts.

| Late production IHC sight base letter code C |

|

International used the late rear sight base. These too were marked with a single letter A through C after late

1953. Most 4.4 millions would have unmarked bases unless they failed testing and the base replaced by International

in late 1953.

International used the late round safety throughout their production. The early rifles had safeties marked

IHC on the side. The mid and late production rifles had the safety marked F. The U marked safety was believed

used by both Springfield and International in early 1950's production.

International follower arms are of the no bevel type. The lugs that the pin goes through are flat on the

bottom and the edges of the arm are rounded from filing or being touched up with a grinder. Earliest IHC producton had

bevel bottomed SA looking follower arms. If an IHC arm is present the rifle more than likely failed testing and should

have some of the other revised parts.

| IHC bullet guide "seashell" swage |

|

are of the post war type that is stamped with the one notch on the side. The swage for the timing leg is

very pronouned and looks like a large deep camila, sea shell or star.

| Early IHC gas plug on right, late type on left |

|

International used two different gas plugs. The first were marked IHC and O in serifed letters, the later

IHC and NHC in san serifed letters. The early IHC and O marked are rare and hard to find.

Rick Berecky has discovered that rear handguards manufactured either by or for Overton were marked in the rear

corner with a little O. After looking at many original mid through late production IHC rifles it has been determined

that this was a handguard used by International. Early IHC production might not have a o marked rear handguard.

It cannot be determined why, the number of truely original rifles is very small. Most are restorations and so are

a tainted collection of parts only as accurate as the current books in use at the time of their rebirth. The accepted

theory is that Springfield provided a vast amount of parts to International and were instructed to helped IHC with production

woes. I can back this theory with early IHC parts that I have discovered that are obviously Springfield manufacture

but have been marked with early International codes which started in late 1953.

In recent posts, handguards from all manufactures and contractors, were packaged in wrap dated 1961 and boxed

in boxes marked 1956. I can't see how this could effect the origin of the o mark. It just proofs the boxes were

made in 1956 and used in 1961. Springfield provide replacement parts to depots. These parts were gather from stores

of parts. Springfield contracted many of the same contractors that manufactured parts for the other M1 manufacturing

Companies. The recent W in a hex with the arrow being another example. Weatherhead manufactured early

IHC elevation pinions, lost the contract with International and started manufacturing them as replacements for Springfield.

New Haven Clock (NHC) elevation pinions, windage knobs and gas plugs. Overton also manufactured replacement

stocks for Springfield after production of new rifles ceased. It would be reasonable to assume that they manufactured

replacement handguards as well.

G.Wayne Bradford is trying to document as many untainted rifles as he can find. We understand that this

is going to be very hard to determine and so the line of what is truely original to International early production will be

gray, not black or white. Collectors need to understand that M1 data is dynamic and changes as more data is

collected from incoming original rifles. The CMP Greek rifles included many original unissued post war rifles from

Springfield and HRA. For many years a small number of collectors have written the data we all have used as fact.

Time will show that some of this data was theory and some of the data was written from "corrected" rifles.

|